Rain Test Lab

The IP waterproof rating tester is designed and manufactured in accordance with the requirements of GB4208-2008 <<Degrees of Protection Enclosures (IP Code)>>, GB4702.2-2005, and GB4706.32-2012. This equipment is widely used by certification and testing organizations for lighting and electrical and electronic products, as well as by quality control departments of manufacturers, for testing products for IPX4, IPX5, and IPX6 waterproof ratings. The device features a standard test option, allowing users to select the desired standard test items and perform the test without any configuration. A custom test option allows users to customize test data to suit different testing standards, ensuring the reliability and accuracy of test data. This complete set of equipment consists of an oscillating pipe rain tester, a handheld shower head, a UL rain fixture, handheld nozzles (φ6.3 and φ12.5), an intelligent water supply system, a rotating stage, and an integrated control cabinet.

RX1043 Oscillating Pipe Rain Tester

Functional Parameters:

1. Suitable for IPX4 testing of products.

2. Oscillating pipe specifications: R1000mm, R1200mm, R1400mm, R1600mm (standard configuration).

3. Total openings: 62/75/87/100 respectively.

4. Oscillating pipe material: Stainless steel.

5. Adjustable oscillation frequency.

6. Drip hole diameter: φ0.4mm.

7. Nozzle angle: 1800° (IPX4).

8. Oscillating angle: 3500° (approximately 3600°) (IPX4).

9. Rainfall rate: 0.07L/min (±5% tolerance) or user-defined parameters.

10. Test time: 10 minutes, adjustable.

11. Housing material: SUS304 stainless steel.

12. Overall dimensions (L×D×H): Approximately 2600×2500×4200mm.

Oscillating Pipe Rain Test

RX1045 Handheld Nozzle

Functional Parameters:

1. Suitable for IPX4 testing of large products.

2. Hole Diameter: φ0.5mm.

3. Number of Holes: 121.

4. Center Hole 1: 24 holes in the inner two circles with an angle of 30°; 96 holes in the outer four circles with an angle of 15°.

5. Nozzle Spherical Diameter: Sφ75.5.

6. Aluminum baffle, stainless steel counterweight.

7. Test Time: 3 minutes, user-settable (controlled by the control system).

Handheld Nozzle

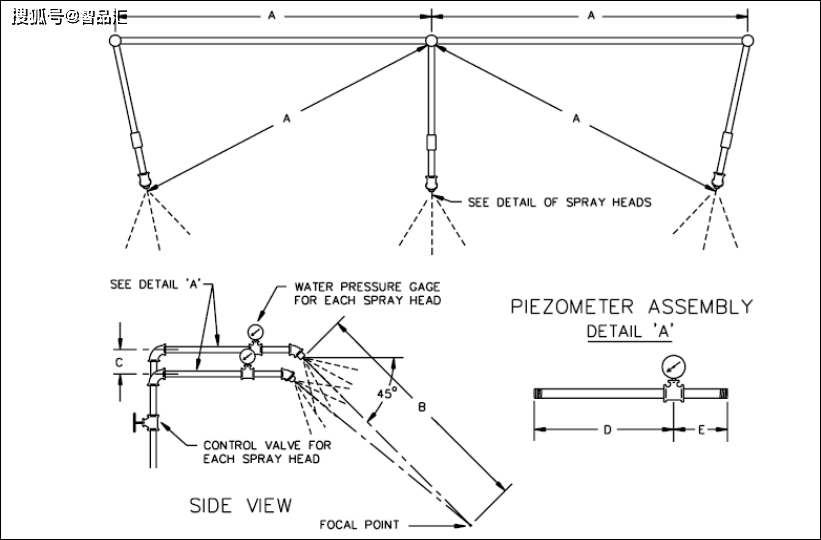

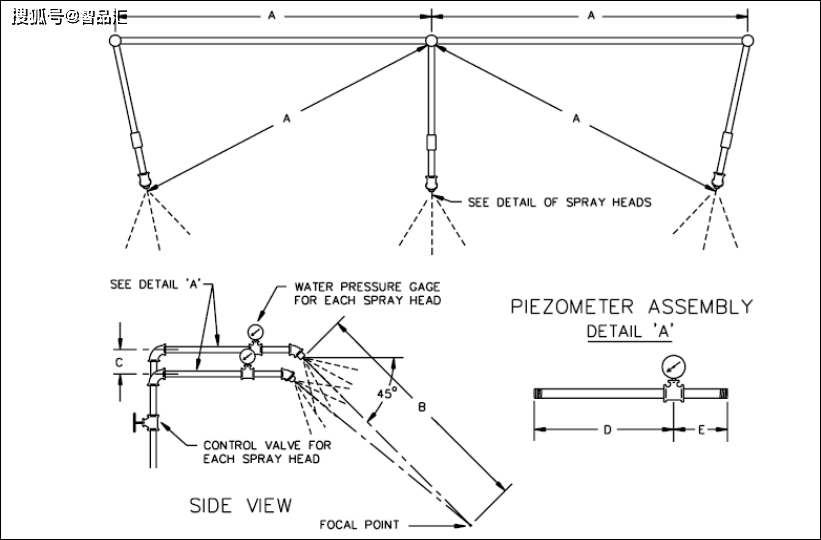

UL Sprayer

I. This sprinkler is designed and manufactured in accordance with the requirements of UL1598, Section 19.17, and the drawings.

Downward-spraying spray stand: 1 set, consisting of the spray stand, three nozzles (purchased from the UL inspection agency), three 150mm Φ pointer-type high-precision pressure gauges for measuring water pressure, with a range of 0 to 0.1 MPa and a resolution of 0.5 kPa), and a water valve.

The spray stand is constructed entirely of welded stainless steel pipe.

The maximum dimensions are approximately: 1500mm wide by 500mm deep. The distances between the pipes meet standard requirements (as shown below). The height is adjustable from 1300 to 2000mm, and four feet allow for fine-tuning of the height.

Designed and manufactured in accordance with the requirements of UL1598 standard, clause 19.17 and the drawings.

Water pumps, water fittings, and related control electronics:

Booster pump: Water delivery rate ≥ 30 L/min ± 5%, maximum water delivery pressure 2.5 kgf/cm². The pump operates on a single-phase AC 220V power supply with a power consumption of approximately 550W.

UL Spray Device

Spray Nozzle

Functional Parameters:

1. Suitable for IPX5 and IPX6 product testing.

2. Aperture: φ6.3mm (IPX5), φ12.5mm (IPX6).

3. IPX5 and IPX6 nozzles with threaded connection and quick-change function.

4. Stainless steel material.

5. Water flow rate: 12.5 ± 0.626 L/min (IPX5), 100 ± 5 L/min (IPX6)

6. Test time: 3 minutes, user-settable (controlled by the control system).

7. Distance between nozzle and housing: 2.5-3m (controlled by the tester).

Sprinkler Nozzle

RX1168 Intelligent Water Supply and Control System

Functional Parameters:

1. Flow Control: Intelligent control, flow rate can be selected and set on the control cabinet.

2. High-flow water supply pump: 0 to 7 m³/h (manually controlled by regulating valve).

3. Low-flow water supply pump: 0 to 3 m³/h (set on the control cabinet screen, digitally controlled by the controller).

4. Flow Control: Real-time monitoring by electronic flow meter, pump speed controlled by frequency converter (for IPX1 to IPX5).

5. IPX6 Flow Control: Manual return valve control.

6. Housing Material: SUS304 stainless steel.

7. Overall Dimensions (L×D×H): 1100×1200×1500mm.

Intelligent Water Supply and Control System

RX1047 Rotatable Sample Stage

Functional Parameters:

1. Turntable Diameter: φ1500mm.

2. Load Capacity: 75kg

3. Turntable Speed: 1-4rpm.

4. Tilt Angle: 15°.

5. Rotation Angle During Testing: 90°, Continuous Rotation.

6. Sample Power Supply Waterproof Socket.

7. Aluminum Alloy Base with Universal Casters.

8. Body Material: SUS304 Stainless Steel

9. Forward/Reverse Rotation and Rotation Controlled by Control Cabinet.

10. Overall Dimensions (L×D×H): 1500×1500×1600mm.

11. Adjustable Height Range: 1200mm–2000mm.

Rotatable Sample Stage

Integrated Control Cabinet

Functional Parameters:

1. Pump Flow Control: Variable Frequency Drive (VFD).

2. Flow Measurement: Electronic flow meter with flow signal feedback.

3. Flow Setting: Set on the control cabinet screen.

4. Controller: PLC.

5. Human-Machine Interface: Touchscreen.

6. Control Functions: Flow control, oscillating pipe shower control, stage control, test time control.

7. Protection Functions: Leakage protection, overload protection, short-circuit protection.

Rain Test Lab

The IP waterproof rating tester is designed and manufactured in accordance with the requirements of GB4208-2008 <<Degrees of Protection Enclosures (IP Code)>>, GB4702.2-2005, and GB4706.32-2012. This equipment is widely used by certification and testing organizations for lighting and electrical and electronic products, as well as by quality control departments of manufacturers, for testing products for IPX4, IPX5, and IPX6 waterproof ratings. The device features a standard test option, allowing users to select the desired standard test items and perform the test without any configuration. A custom test option allows users to customize test data to suit different testing standards, ensuring the reliability and accuracy of test data. This complete set of equipment consists of an oscillating pipe rain tester, a handheld shower head, a UL rain fixture, handheld nozzles (φ6.3 and φ12.5), an intelligent water supply system, a rotating stage, and an integrated control cabinet.

RX1043 Oscillating Pipe Rain Tester

Functional Parameters:

1. Suitable for IPX4 testing of products.

2. Oscillating pipe specifications: R1000mm, R1200mm, R1400mm, R1600mm (standard configuration).

3. Total openings: 62/75/87/100 respectively.

4. Oscillating pipe material: Stainless steel.

5. Adjustable oscillation frequency.

6. Drip hole diameter: φ0.4mm.

7. Nozzle angle: 1800° (IPX4).

8. Oscillating angle: 3500° (approximately 3600°) (IPX4).

9. Rainfall rate: 0.07L/min (±5% tolerance) or user-defined parameters.

10. Test time: 10 minutes, adjustable.

11. Housing material: SUS304 stainless steel.

12. Overall dimensions (L×D×H): Approximately 2600×2500×4200mm.

Oscillating Pipe Rain Test

RX1045 Handheld Nozzle

Functional Parameters:

1. Suitable for IPX4 testing of large products.

2. Hole Diameter: φ0.5mm.

3. Number of Holes: 121.

4. Center Hole 1: 24 holes in the inner two circles with an angle of 30°; 96 holes in the outer four circles with an angle of 15°.

5. Nozzle Spherical Diameter: Sφ75.5.

6. Aluminum baffle, stainless steel counterweight.

7. Test Time: 3 minutes, user-settable (controlled by the control system).

Handheld Nozzle

UL Sprayer

I. This sprinkler is designed and manufactured in accordance with the requirements of UL1598, Section 19.17, and the drawings.

Downward-spraying spray stand: 1 set, consisting of the spray stand, three nozzles (purchased from the UL inspection agency), three 150mm Φ pointer-type high-precision pressure gauges for measuring water pressure, with a range of 0 to 0.1 MPa and a resolution of 0.5 kPa), and a water valve.

The spray stand is constructed entirely of welded stainless steel pipe.

The maximum dimensions are approximately: 1500mm wide by 500mm deep. The distances between the pipes meet standard requirements (as shown below). The height is adjustable from 1300 to 2000mm, and four feet allow for fine-tuning of the height.

Designed and manufactured in accordance with the requirements of UL1598 standard, clause 19.17 and the drawings.

Water pumps, water fittings, and related control electronics:

Booster pump: Water delivery rate ≥ 30 L/min ± 5%, maximum water delivery pressure 2.5 kgf/cm². The pump operates on a single-phase AC 220V power supply with a power consumption of approximately 550W.

UL Spray Device

Spray Nozzle

Functional Parameters:

1. Suitable for IPX5 and IPX6 product testing.

2. Aperture: φ6.3mm (IPX5), φ12.5mm (IPX6).

3. IPX5 and IPX6 nozzles with threaded connection and quick-change function.

4. Stainless steel material.

5. Water flow rate: 12.5 ± 0.626 L/min (IPX5), 100 ± 5 L/min (IPX6)

6. Test time: 3 minutes, user-settable (controlled by the control system).

7. Distance between nozzle and housing: 2.5-3m (controlled by the tester).

Sprinkler Nozzle

RX1168 Intelligent Water Supply and Control System

Functional Parameters:

1. Flow Control: Intelligent control, flow rate can be selected and set on the control cabinet.

2. High-flow water supply pump: 0 to 7 m³/h (manually controlled by regulating valve).

3. Low-flow water supply pump: 0 to 3 m³/h (set on the control cabinet screen, digitally controlled by the controller).

4. Flow Control: Real-time monitoring by electronic flow meter, pump speed controlled by frequency converter (for IPX1 to IPX5).

5. IPX6 Flow Control: Manual return valve control.

6. Housing Material: SUS304 stainless steel.

7. Overall Dimensions (L×D×H): 1100×1200×1500mm.

Intelligent Water Supply and Control System

RX1047 Rotatable Sample Stage

Functional Parameters:

1. Turntable Diameter: φ1500mm.

2. Load Capacity: 75kg

3. Turntable Speed: 1-4rpm.

4. Tilt Angle: 15°.

5. Rotation Angle During Testing: 90°, Continuous Rotation.

6. Sample Power Supply Waterproof Socket.

7. Aluminum Alloy Base with Universal Casters.

8. Body Material: SUS304 Stainless Steel

9. Forward/Reverse Rotation and Rotation Controlled by Control Cabinet.

10. Overall Dimensions (L×D×H): 1500×1500×1600mm.

11. Adjustable Height Range: 1200mm–2000mm.

Rotatable Sample Stage

Integrated Control Cabinet

Functional Parameters:

1. Pump Flow Control: Variable Frequency Drive (VFD).

2. Flow Measurement: Electronic flow meter with flow signal feedback.

3. Flow Setting: Set on the control cabinet screen.

4. Controller: PLC.

5. Human-Machine Interface: Touchscreen.

6. Control Functions: Flow control, oscillating pipe shower control, stage control, test time control.

7. Protection Functions: Leakage protection, overload protection, short-circuit protection.

Zhipinhui After-Sales Policy:

*After-Sales Hotline: +864008166687

1. Our company has assembled a team of experienced field engineers and senior technicians to promptly respond

to any equipment issues and provide after-sales maintenance.

2. Within China, within one week of new product delivery, our after-sales technical staff will install the equipment and

provide after-sales training at the customer's location, using the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within one hour. Within 3-5 hours within the province,

and within 24-48 hours outside the province, we will arrive at the customer's site,

determine the appropriate action based on the complaint, and provide after-sales repairs. (Domestic)

4. For international travel, our company can also arrange for an after-sales engineer to visit you for installation and

commissioning. Please discuss any travel and catering issues in advance.

We also provide video installation guides for you to choose from, providing you with a comprehensive and multi-faceted solution.

5. Any material costs related to product quality during the warranty period will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use or environmental factors.

The materials and accessories used for repairs will be charged at cost only.