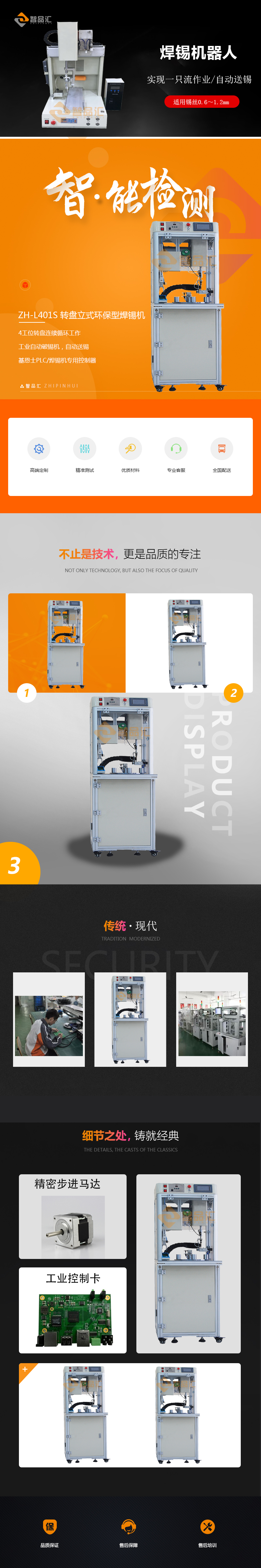

ZH-L401S转盘立式环保型焊锡机Rotary Vertical Environmental Protection Type Soldering Robot

自动焊锡机 Automatic soldering machine | ZH-L401S |

加工范围 Processing range X/R1/Z/R2 | 根据需要定制 Customized as needed |

R1轴平台最大负载 R1-axis platform maximum load | 30kg |

X/Y/Z轴移动速度 X/Y/Z axis movement speed (mm/sec) | 0-1000 |

XYZ轴重复精度 XYZ Axis Repeatability | <±0.02mm |

编程方式 Programming method | 示教盒/触摸屏 Teaching box/Touch screen |

控制方式 Control mode | 日本基恩士PLC/焊锡机转用控制器 Japan Keyence PLC/Solder Diversion Controller |

马达系统 Motor system | 步进级精密马达 Stepping precision motors |

传动方式 Transfer method

| 进口同步带+ HIWIN精密直线导轨 Imported synchronous belt + HIWIN precision linear guide rail |

焊台功率 Soldering station power | 大功率150W High power 150W |

温度范围 Temperature range | 0-500° |

自动破锡器 Automatic tin-breaker | 送锡精准.百分百破锡. Send tin precisely. 100% tin break. |

适用锡丝 Applicable tin wire | 0.6-1.2MM |

专利型真空吸洗机构 Patented vacuum suction mechanism | 锡渣回收方便 Tin slag is easily recycled |

锡烟处理 Tin smoke treatment | 工业抽烟过滤器 Industrial smoke filter |

输入电源 Input power | AC220V(内部开关转换 Internal switch conversion) |

外形尺寸 Dimensions | L600*W500*H1800 |

机器重量 Machine weight | 100KG |

功能特点Functional characteristics

1.4工位转盘工位连续循环工作,根据加载自动上料和下料机构,实现一只流作业。The four-station turntable work station continuously circulates, and according to the loading automatic feeding and discharging mechanism, one flow operation can be realized.

2.工业自动破锡机构,精准送锡Industrial automatic tin-breaker, delivery tin accurately.

3.内设堵锡、卡锡、无锡线检测功能It is equipped with tin plug, tin stuck and tin line detection function.

4.专利型真空清洗烙铁头机构,对机器清洁或锡渣回收更大提高。The patented vacuum cleaning iron head mechanism to make the machine cleaning or tin slag recovery capability is greatly improved.

5.焊锡锡烟可以根据通过管道排放或直接过滤,避免因焊锡工长期吸入焊锡烟雾而引起职业病。Solder tin smoke can be eliminated through the pipeline or directly filtered to solve occupational diseases in soldering jobs.

Zhipinhui After-Sales Policy:

*After-Sales Hotline: +864008166687

1. Our company has assembled a team of experienced field engineers and senior technicians to promptly respond

to any equipment issues and provide after-sales maintenance.

2. Within China, within one week of new product delivery, our after-sales technical staff will install the equipment and

provide after-sales training at the customer's location, using the contact information and address provided by the customer.

3. All complaints related to product quality will be responded to within one hour. Within 3-5 hours within the province,

and within 24-48 hours outside the province, we will arrive at the customer's site,

determine the appropriate action based on the complaint, and provide after-sales repairs. (Domestic)

4. For international travel, our company can also arrange for an after-sales engineer to visit you for installation and

commissioning. Please discuss any travel and catering issues in advance.

We also provide video installation guides for you to choose from, providing you with a comprehensive and multi-faceted solution.

5. Any material costs related to product quality during the warranty period will be borne by our company.

6. During the warranty period, we will provide free repairs due to improper use or environmental factors.

The materials and accessories used for repairs will be charged at cost only.