Temperature rise test requirements for terminals and connectors – Standards IEC 60947-7-1/2 and UL 1059

Temperature rise testing is a key electrical test for safety certification of terminal blocks. The purpose of this test is to measure the temperature change of the terminal block after applying a test current, to determine whether it meets the requirements of the relevant standards. The standards for temperature rise testing of terminal blocks are IEC 60947-7-1/2 for the IEC standard and UL 1059 for the US standard.

What is a terminal block temperature rise test?

A terminal block temperature rise test evaluates the performance of a terminal block (or connector) and its insulating

housing as a whole under rated current, overcurrent, and short-circuit conditions. The temperature rise caused by the

Joule effect in the terminal block should be minimized, which requires low contact resistance in the circuit.

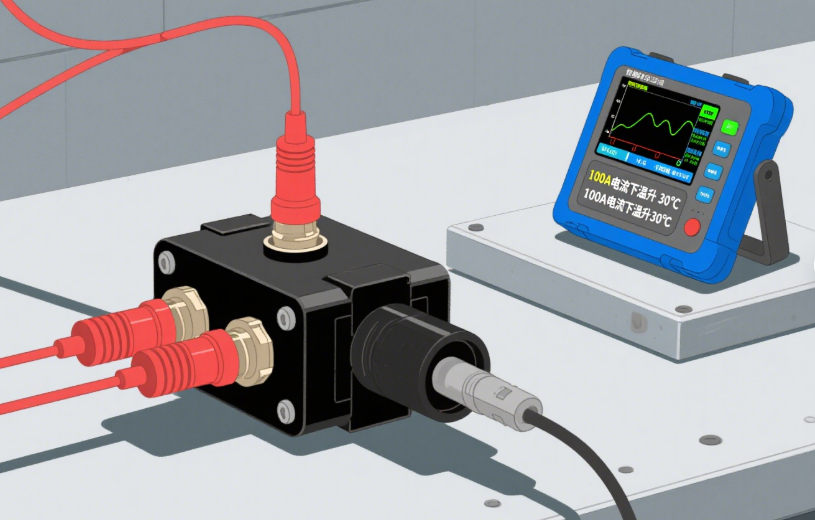

The temperature rise test records the temperature increase of the terminal block after applying a test current at room temperature.

Unless otherwise specified, such as using a current value consistent with the electrical equipment, the rated current

value of the terminal or connector should be used during the test. For terminal blocks (or connectors) that comply

with IEC 512-3, IEC 60998-1/EN 60998-1/DIN-VDE 0613 Part 1 standards, and for rail-mounted terminal blocks that

comply with IEC 60947-7-1/EN 60947-7-1/DIN-VDE 0611 Part 1 standards, the temperature rise during the test must

not exceed 45K. The general rule for connector standards is that the temperature rise should not exceed 30K.

For example: If the ambient temperature is 25°C and the measured temperature is 70°C,

the temperature rise is 70°C - 25°C = 45K. If the temperature rise exceeds this value, the terminal block fails the test.

When selecting a connector, users should pay attention to the connector's structural requirements and current

carrying capacity.

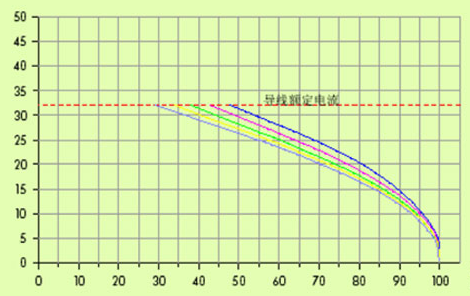

Current carrying capacity depends on the cross-sectional area of the connected wire, ambient temperature,

the number of conductors carrying current simultaneously, the internal resistance of the connector, the printed

circuit board layout, and the connector material. According to IEC/EN 60512-5-2, a current carrying capacity

curve (derating curve) can show the relationship between current, ambient temperature, and temperature

rise (up to the connector's maximum operating temperature). The connector can only operate correctly within its

maximum operating temperature range (the sum of self-generated heat and ambient temperature).

Temperature Rise Test Requirements for Terminal Blocks

IEC 60947-7-1/-2

In the test, five terminal blocks are mounted horizontally on a rail and connected in series with a 1-meter or 2-meter

wire of the rated cross-sectional area. A test current, equal to the rated current carrying capacity of the wire,

is applied to the terminal blocks. The temperature rise of the middle terminal block is recorded. At a room

temperature of +20°C, the maximum permissible temperature rise for the terminal block is 45 K (Kelvin). After the test,

a voltage drop test is also performed on the terminal block.

UL 1059

This test procedure is essentially the same as the IEC test, except for the wire length. In the UL 1059 test, three terminal

blocks are mounted horizontally (adjacent to each other). The ambient temperature during measurement is 25°C,

and the maximum permissible temperature rise is 30 K (measured as close to the connection point as possible).

Terminal blocks using high-quality contact materials will have a temperature rise lower than the specified standard

requirement. High-quality copper and reliable connection transitions significantly reduce the contact resistance of the terminal block.